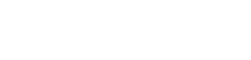

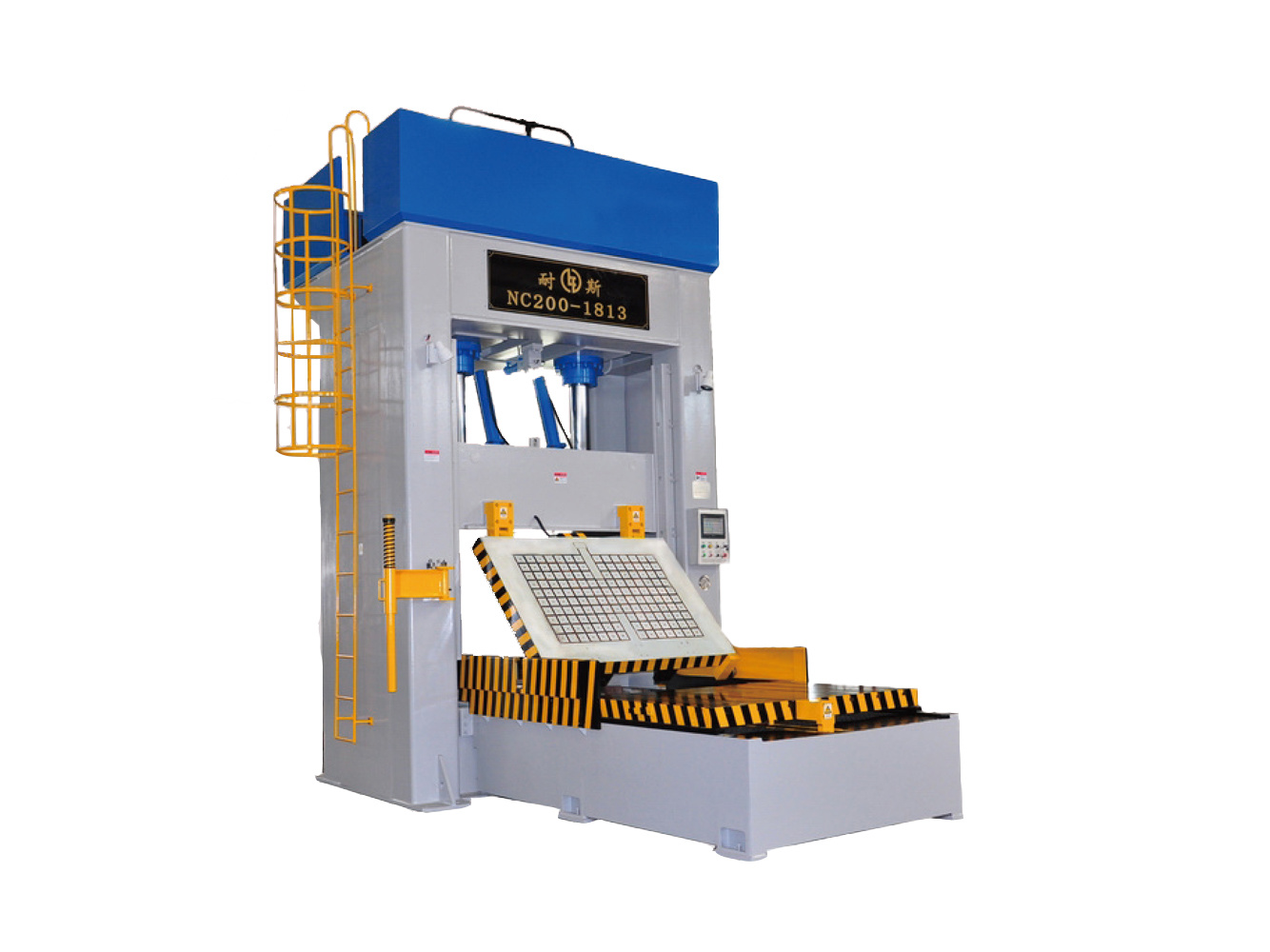

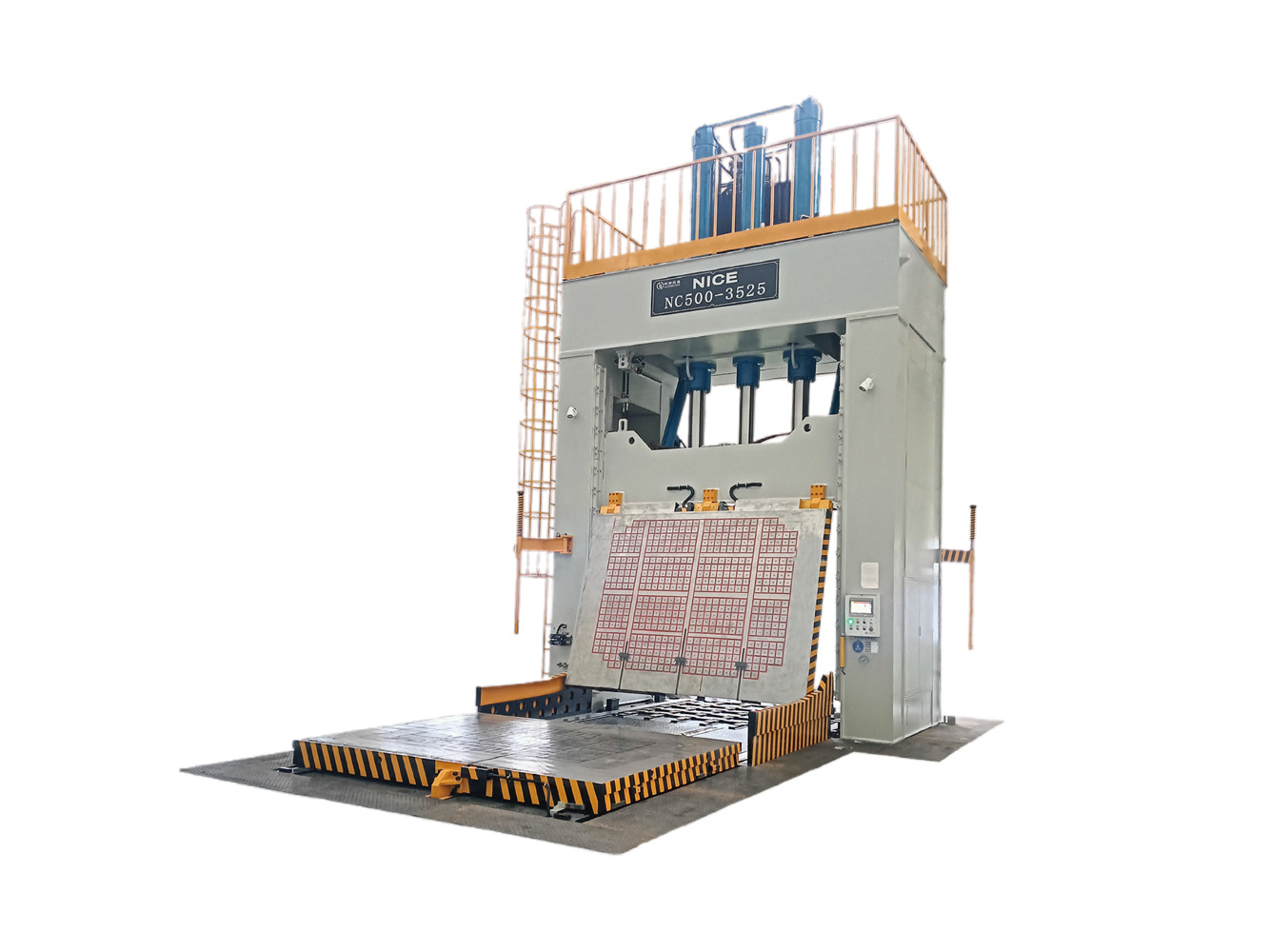

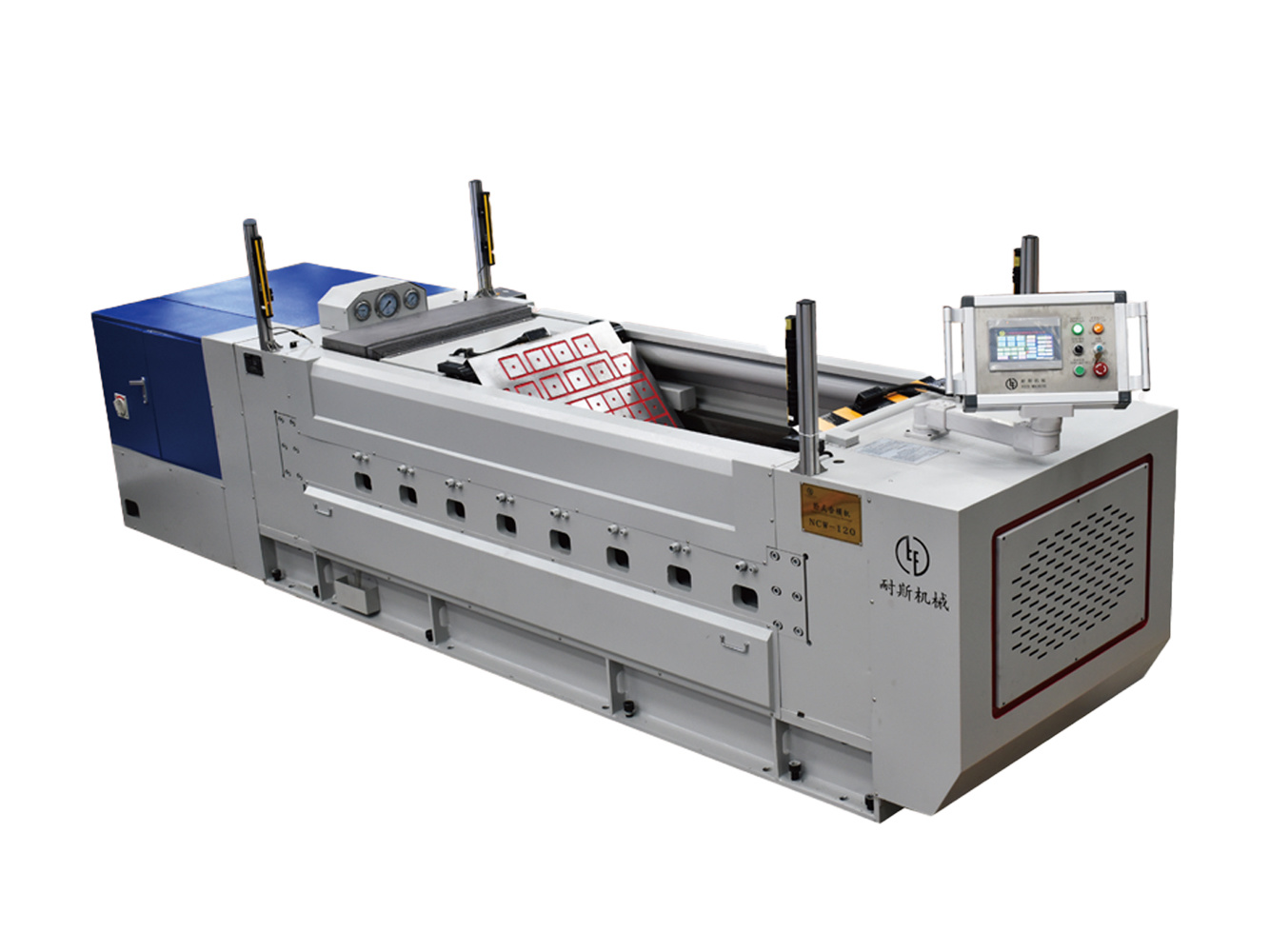

NC series vertical molding machine

Category:

Keyword:

Case Description

- Product Description

-

The NC series vertical mold clamping machine is a major product designed and developed by our company, absorbing the essence of similar products at home and abroad. This product is mainly used for the repair of various plastic molds and metal die-casting molds. Its application has brought revolutionary changes to the mold industry, replacing the previous crude mold flying method using copper rod knocking with a simple and quick automatic method, greatly improving the efficiency and precision of mold flying.

Product Features:

1. Small tonnage models (below 200T) use a welded frame structure, while large tonnage models (above 300T) use a welded split frame structure. The split sections are tightened with Greene columns and screws. Both the frame and the slide are tempered to eliminate stress, resulting in high rigidity and minimal deformation.

2. The upper and lower worktables and guide rails of the pressure plate type mold clamping machine are made of ductile iron, with hand-scraped surfaces for good flatness, high precision, and small deformation.

3. The disc-type mold clamping machine uses an electrically controlled permanent magnet disc. The magnetism remains even when the power is off, requiring only simple magnetization and demagnetization operations. After magnetization, the power can be cut off without losing magnetism. It requires no power during use, has strong magnetism, and is both safe and energy-saving.

4. Complete safety devices include safety light curtains, anti-drop cylinders, locking cylinders, and safety support frames.

5. The hydraulic system uses a shock absorption device to reduce hydraulic impact and ensure equipment precision.

6. The hydraulic system has a low-pressure protection device to prevent damage from collisions or piercing.

7. The system can use high-speed mold clamping to create an impact, resulting in excellent vermilion printing effects.

Technical Parameters:

Model Maximum Clamping Force (T) Maximum Lifting Force (T) Mold Opening Space (mm) Main Cylinder Stroke (mm) Worktable Dimensions (mm) Upper Worktable Load Capacity (T) Lower Worktable Load Capacity (T) Ejection Force (T) Ejection Cylinder Stroke (mm) Lower Worktable Ejection Stroke (mm) Motor Power (KW) Machine Dimensions (mm) NC30-0806 30 12 1000 900 800X600 0.5 2 3 100 1400 3.7 2680X2180X3300 NC70-1007 70 20 1100 1000 1000X700 1 3 3 100 1600 5.5 3080X2150X4060 NC120-1310 120 40 1300 1200 1300X1000 3 8 3 100 2200 7.5 3830X2680X4350 NC160-1612 160 50 1500 1400 1600X1200 5 10 3 100 2600 11 4600X3380X5490 NC200-1813 200 60 1800 1700 1800X1300 7 16 5 100 2800 15 4800X3660X6000

Leave a message

We attach great importance to your opinions and inquiries. If you have any questions about our products and services, please fill out the following form, and we will contact you as soon as possible.

CONTACT

Contact Us

Service Hotline

Monday to Saturday 8:30-18:00

Jiangxi Naisi Machinery Manufacturing Co., Ltd.

Luliang West Avenue, Industrial Park, Xiushui County, Jiujiang City, Jiangxi Province

Tel:0792-7910688

Dongguan Naisi Machinery Manufacturing Co., Ltd.

Address: Room 102, Building 2, No. 2 Chaoheng Road, Chashan Town, Dongguan City, Guangdong Province

Follow the official public account

Follow the company website

MESSAGE

Online Message

We attach great importance to your opinions and inquiries. If you have any questions about our products and services, please fill out the following form, and we will contact you as soon as possible.